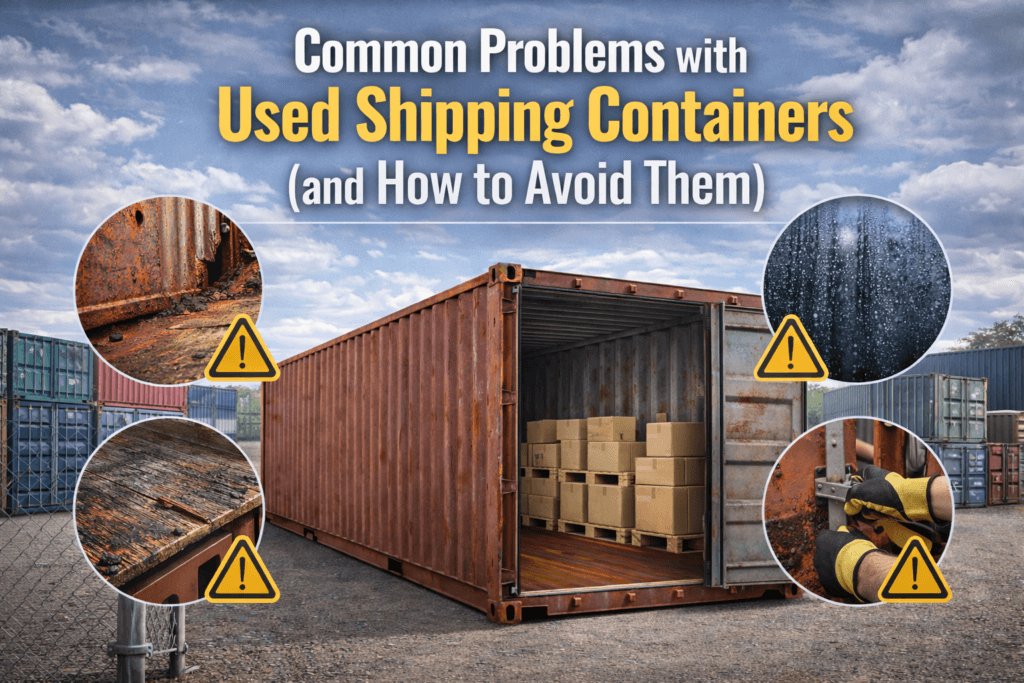

Common problems with used shipping containers (and how to avoid them) typically include surface rust, condensation, worn flooring, stiff doors, and hidden structural damage. These issues are common with used units but are usually manageable when buyers understand container condition, inspection points, and correct site setup. In the UK, most container problems come from poor preparation rather than the container itself.

Used shipping containers remain a popular choice for secure storage, site use, and workshops. They offer strong value and fast availability. Problems tend to arise when buyers focus purely on price and not suitability.

This guide explains the most common issues found with used shipping containers and how to avoid them.

Rust and Corrosion

Why rust is common on used shipping containers

Used containers have often spent many years at sea. Exposure to salt air and harsh weather leads to surface rust, particularly around door frames, roof edges, and weld seams.

Surface rust is normal and does not affect structural strength. Deeper corrosion around load-bearing areas is what requires closer inspection.

Used shipping containers are made from weathering steel, which develops surface rust that can help protect the underlying metal when properly maintained.

How to avoid rust problems

- Choose containers sold as wind and watertight

- Inspect roof panels for soft spots or pitting

- Check corner castings and bottom rails for heavy corrosion

- Treat or repaint exposed steel once installed

With basic maintenance, a used container can last many years on land.

Condensation and Moisture Build-Up

Why condensation occurs inside containers

Shipping containers are steel structures with limited airflow. In the UK climate, temperature changes cause moisture to form inside, especially overnight.

Condensation is one of the most common issues reported by buyers storing tools, stock, or furniture.

Sitting a container directly on soil or grass accelerates corrosion along the bottom rails

How to reduce condensation risk

- Raise the container off the ground to allow airflow

- Avoid sealing damp items inside

- Use moisture traps or desiccants

- Improve ventilation for long-term storage

- Consider insulation for sensitive contents

Condensation control depends on setup, not container age.

Worn or Damaged Flooring

Why container floors matter

Most used shipping containers have marine plywood flooring. Forklift traffic and heavy loads can cause wear, staining, or delamination over time.

A damaged floor can affect hygiene, safety, and long-term storage suitability.

How to check and protect the floor

- Inspect for soft spots or lifting edges

- Ask whether the floor has been repaired or sealed

- Use pallets, boards, or rubber matting for heavy items

A solid floor is essential for secure storage.

Door and Locking Issues

Why used container doors can feel stiff

Used shipping container doors are made from heavy steel and rely on multiple locking bars and cam keepers. After years of use and exposure to weather, it is common for doors on used containers to feel stiff or require more force to open and close.

Stiff doors do not automatically indicate poor condition. In many cases, this is due to age, lack of lubrication, or minor frame movement during transport.

How to avoid access problems

- Open and close both doors fully during inspection

- Check locking bars engage correctly

- Inspect door seals for splits or compression

- Lubricate hinges and locking gear after delivery

- Fit a lockbox to improve security

Most door stiffness is easily resolved with basic maintenance.

Hidden Structural Damage

Where damage is often missed

Some structural issues are not immediately obvious. Large Dents in side panels, roof deflection, or bent rails can compromise water resistance and strength.

Problems often occur when containers are bought unseen or without inspection.

How to avoid structural surprises

- Buy from a UK supplier that inspects containers before sale

- Request recent photos or view the unit in person

- Avoid containers sold as clearance or scrap grade

- Match container condition to intended use

Not all used containers are the same.

Odours and previous cargo

Some used shipping containers may retain odours from previous cargo. While this is not usually a structural issue, it can affect suitability for storing furniture, textiles, food packaging, or retail stock.

Odours are more common in containers that previously carried goods such as timber, chemicals, or agricultural products, and should be checked before purchase if contents are sensitive.

Age and Remaining Lifespan

Why container age matters

Used shipping containers typically range from 10 to 15 years old. While many continue to perform well, they do not offer the same remaining lifespan as new one trip units.

For buyers planning very long-term storage with minimal maintenance, this difference can be important.

Repainting exposed steel helps seal existing rust and extend the usable life of a used container.

Making the right choice

- Used containers suit short to medium-term storage

- New containers suit long-term or low-maintenance use

- Budget savings should be weighed against future plans

Choosing the right container first avoids replacement costs later.

Comparison: Inspected Used Containers vs Poorly Described Units

The table below explains how a properly inspected used container compares with poorly described units often found online.

| Factor | Inspected Used Container | Poorly Described Unit |

|---|---|---|

| Condition | Wind and watertight | Often unclear |

| Floor | Marine plywood | Worn or damaged |

| Doors | Functional but may be stiff | Often unchecked |

| Lifespan | Predictable | Uncertain |

| Aftercare | Supplier support | None |

Clear information reduces risk.

Why Bosh Boxes Is the Right Choice

- All used containers inspected before sale

- Wind and watertight guarantee as standard

- Honest condition descriptions

- UK-wide container delivery

- Advice based on real use cases

- Options for future container conversions

Buying correctly once saves money long term.

Frequently Asked Questions About Used Shipping Containers

Are used shipping containers waterproof?

Most used shipping containers are sold as wind and watertight. This means they keep out rain and wind under normal UK weather conditions, but they are not fully airtight.

Is surface rust on a used container a problem?

Surface rust is normal on used shipping containers and does not affect strength. Structural corrosion around the roof, corner posts, or bottom rails is what needs closer inspection.

Why are the doors stiff on some used containers?

Stiff doors are common on used containers due to age, heavy steel components, and exposure to weather. In most cases, lubrication and adjustment restore smooth operation.

Can I use a used container for long-term storage?

Yes, a used container can be suitable for long-term storage if it is structurally sound, wind and watertight, and correctly sited. Condensation control and basic maintenance are important.

How long will a used shipping container last?

A well-maintained used shipping container can last 10 to 15 years or more when used for static storage in the UK. Actual lifespan depends on condition, placement, and upkeep.

Are used containers secure?

Used shipping containers are very secure due to their steel construction. Adding a lockbox and high-quality padlock improves protection further.

How to Avoid Problems Before You Buy

- Define what you are storing and for how long

- Choose condition over cheapest price

- Inspect the container or request detailed photos

- Prepare the site before delivery

- Ask questions about flooring, doors, and seals

Most problems are avoidable with the right checks.

How to Get Started

If you are considering used shipping containers for sale in the UK, speak to a supplier that explains both benefits and limitations clearly.

For advice on condition, lifespan, and fast container delivery UK-wide, contact Bosh Boxes today